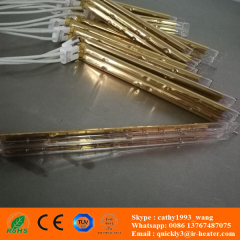

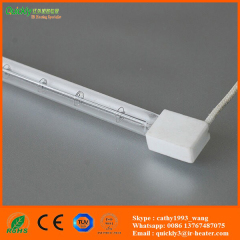

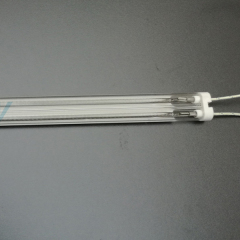

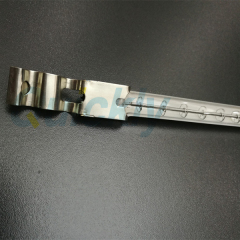

IR heating lamps with ceramic white coating

| Price: | 20.0 USD |

| Payment Terms: | T/T,L/C,WU,Paypal |

| Place of Origin: | Anhui, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1. reflector can concentrate the heat, increasing the effectiveness of the heat output.

2. emitters with coating are highly economical.

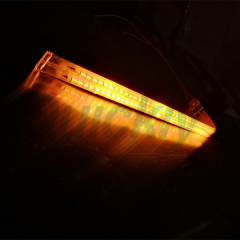

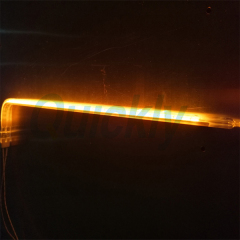

Advantages of Infrared Radiation Quartz glass infrared emitter frequently prove superior to conventional heating sources such as warm air, steam, ceramic, gas or metal emitters, because they transfer large amounts of energy very quickly and can be precisely matched to the product and the manufacturing step-the ideal heating process. -Infrared radiation requires neither contact nor intermediate transfer medium-Quartz glass infrared emitters are precisely matched to the materials to be heated-Fast response times allow controllable heat-Heat is applied precisely where and only for so long as it is required IR Lamps Applications:

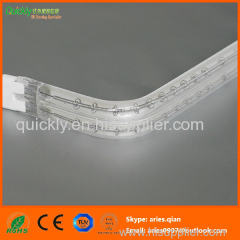

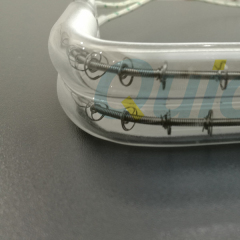

Many sensitive heating processes run faster, more efficiently and more stable when infrared emitters with the QRC reflector are used. A reflector helps to target infrared radiation. The QRC (quartz reflective coating) reflector consists of high purity quartz material, which is a coating on the tube. As a result, the emitter is very compact and requires very little working space. The nano reflector has very good heat resistance and is also resistance to acids, alkalis and other aggressive substances. Consequently, emitters with this reflector can be used even in manufacturing process where the manufacturing plant requires regular cleaning with corrosive cleaning agents. Heating process can be carried out significantly better in vacuum, for example for the production of solar cells. New are QRC heaters which are bent or formed to fit exactly to edges or contours of a product. This helps to target heat e.g. For deburring or welding of three dimensional plastics products.

Related Search

Find more related products in following catalogs on Hisupplier.com

Company Info

You May Like:

Product (3704)

- Infrared Heat Lamps (1909)

- Infrared Emitters (1723)

- Ruby Lamps (50)

- End Base (13)

- Lamp Accessory (9)