quartz infrared lamps for industrial oven

| Price: | 18.0 USD |

| Payment Terms: | T/T,WU,Paypal |

| Place of Origin: | Anhui, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

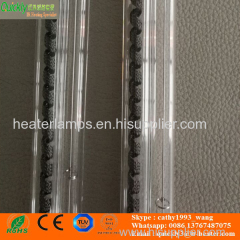

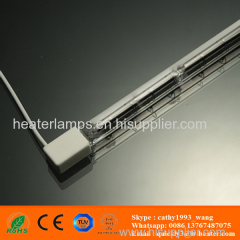

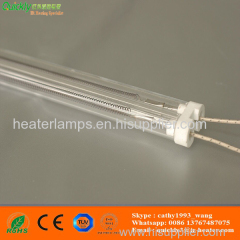

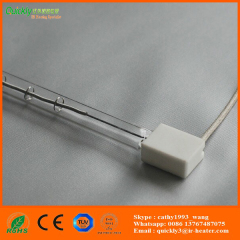

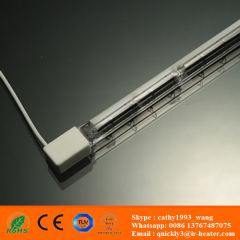

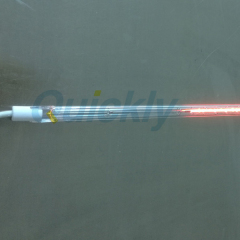

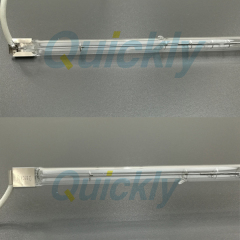

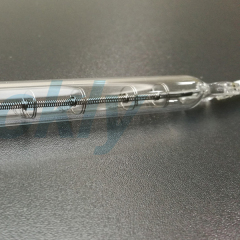

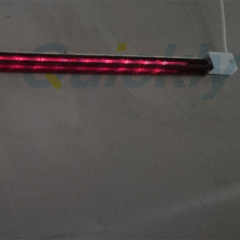

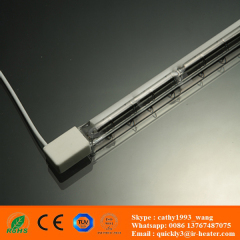

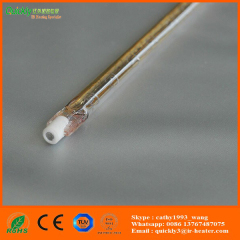

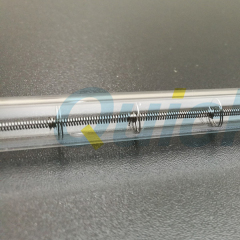

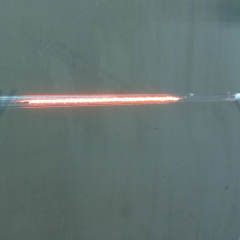

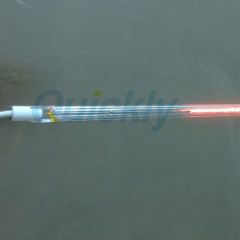

Short wave double tube ir heater lamp

1. Peak Wavelength range: 1.0-1.4um;

2. Response time: 1 second;

3. Max Temp: 950 Degree C.

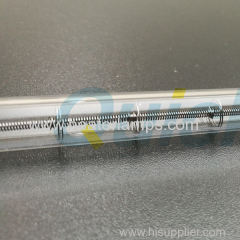

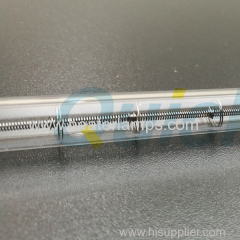

Twin Tubes Quartz Halogen IR Heater Lamps

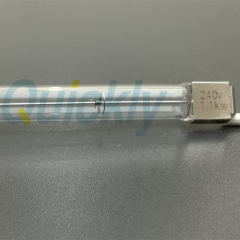

Specification

1.Voltage:12-480v

2.Watts: 10-10000w

3.Length: 90-4000mm

4.Diameter: 23*11mm, 33*15mm

4. Long Life: 5000H on average electric heat tube

5. High Speed: within a second to switch on.

6. High efficiency: more than 85% heat efficiency of full power.

7. High power density: up to 110W/cm

Spec as per customer's request

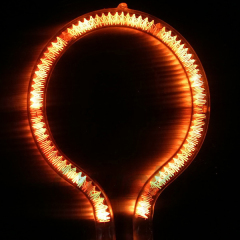

Advantages

1. Wide range of lamps lengths and power available

2.. Instant heat: More than 90% emission within 1 second

3. Clean: No byproducts, no pollution

4.Safe: Quartz envelope, heat shock resistant

5.Economical: More than 85% of consumed energy transmitted into infrared heat

6. Fully dimmable: Fully controllable accurately(0% to 100%)

7.Possibility to put people sensor: On/Off switches do not affect life time of the lamps

8.Long life: More than 5000 hours

9.Heat can be focused: Same optical properties as light, can be directed by reflectors

10.No air draughts: because of radiation

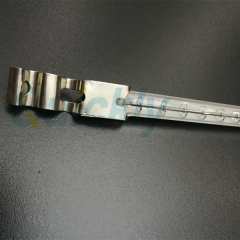

11.Compact and easy to install

Applications

Workshop

RFQ

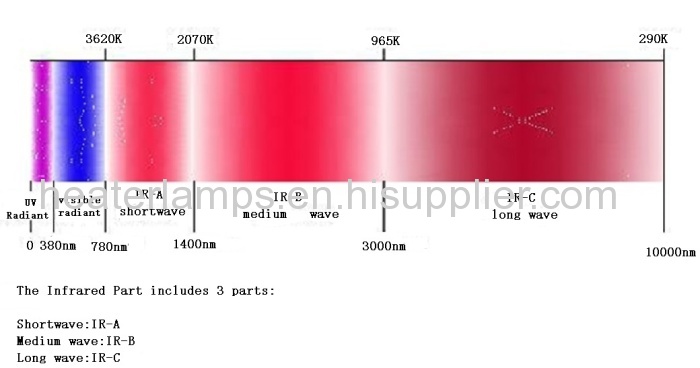

1. What is Infrared Radiation

Infrared heating is a kind of radiation heating. By infrared radiation (light) infrared light from material in the form of molecular (atomic) resonance absorption, so as to achieve the objects for the purpose of heating. The wavelength of the radiation heating mode to match, the selective penetration, directional and directly to heating surfaces and a certain depth, is a very efficient way of heating, drying and curing.

2. How to choose correct wavelength IR emitter

Depending on the temperature of the heating element,an infrared emitter delivers distinctly different radiation at various wavelengths.

It is important to select the correct emitter for the product,as the wavelength has a significant influence on the heating process.

Short wave radiation can penetrate deep into some solid materials and ensure a uniform through heating.

Medium wave radiation is absorbed mostly in the outer surface and predominantly heats the surface.Medium wave radiation is particularly well absorbed by many plastics.glass and especially water and is converted directly into heat.

3. The importance of correct wavelength infrared emitter choosing

To achieve successful process heating,it is important that the infrared emitter is carefully matched to the properties of the product to be heated in terms of its wavelength,its shape and its power output.Radiation which precisely matches the absorption characteristics of the product is quickly converted into heat in the product,without unnecessary heat being transferred to the surroundings.

It also saves time and money if products can be transferred quickly for further processing after the heating stage.

4. Package and Shipping

5. Delivery Time

100pcs, 5-7 working days, specific time depends on the lamp's quantity, shape, complexity of craft process...

Related Search

Find more related products in following catalogs on Hisupplier.com

Company Info

You May Like:

Product (3704)

- Infrared Heat Lamps (1909)

- Infrared Emitters (1723)

- Ruby Lamps (50)

- End Base (13)

- Lamp Accessory (9)